- Single Spiral Quick Freezing Machine

-

- Brand:GELGOOG

- PAY METHOD:WEST UNION L/C T/T CASH

- Warranty Time:12 Months

- Country Of Origin:China

- Features

- Technical Data

- FAQ

Introduction:

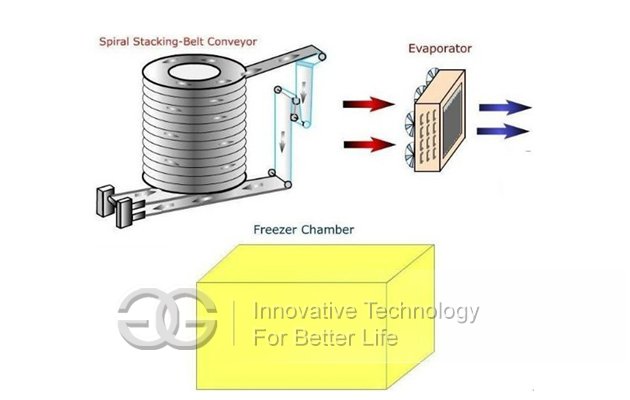

This spiral quick freezer is suitable for wheaten food, meat food, aquatic food, fried food and ice-cream processing. Main structure as below

1.Conveyor: uses stainless steel special three chain conveyor. (more reasonable structure, more compact volume, higher quick freezing effect, save more energy)

2.Body size: 4150*2910*3400mm. Inlet length 1000mm; outlet length 500mm. Body uses flame-retardant polyurethane sandwich insulation panels, panels thickness 120mm.

3.Inlet uses dual-channel low temperature resistance, anti-aging, oil-resistance, seal tightly.

4.Insides parts: mainly have frame, spindles etc hot dip galvanized carbon steel; Rail bracket, duct plate and water tray is stainless steel material, contacting belt parts are all ultra-high molecular weight polyethylene material.

With the fast development of freezing industry, a new series freezer which is smaller and high-efficient machine GWL spiral freezer has become the most popular one in the food company. It is adopts top blow or lateral blow, the freezing time can be adjust 10min to 60min.

Advantage:

(1) Aluminum evaporators, different fin pitches; Outer bracket is made of SUS304 stainless steel;

(2) Axial fans: stainless steel air box, aluminum blades. Closed type, moisture and water proof motor;

(3) Spiral tower and bracket made of stainless steel, the pontes between the mesh belt is made of macromolecule polyethylene anti-frication material;

(4) Stainless steel conveyor belt, equipped with safe guard both sides;

(5) Drive motor installed outside of the refrigerator with no oil inside the refrigerator and convenient to maintain;

(6) Sandwich PUF panels laminated by stainless steel sheet both sides;

(7) The bottom panels are equipped with drainage slot in the bottom board to prevent ponding and avoid cold bridge;

(8) Door is equipped with frame heating device;

(9) The wind drum, inlet device, outlet device and all structure parts are made of stainless steel;

(10) Control panel is made of stainless steel, PLC and touch screen control displaying data for time, working status, frozen time, inner temperature, conveyor speed and ect.

| Name | Single Spiral Quick Freezing Machine |

| Capacity | 300kg/h |

| Processing product | Restructuring Molding fried Fish fingers, vacuum pack surimi sticks |

| In-feed temperature | +40℃ |

| Out-feed temperature | -18℃ |

| Inside temperature | -35℃ |

| Freezing time | 12-60mm(adjustable) |

| Refrigerant duty | 60KW |

| Evaporating temperature | -42℃ |

| Freezer power | 9KW |

| Belt width | 360mm |

| Drum diameter | 950mm |

| Layer No. | 15 layers |

| Effect height | 80 |

| Weight | 8T |

| Evaporating area | 500 square meter |

| Dimension | 4150*2910*3340mm(library entry) |

1.Q: What is the voltage/phase for this machine?

A: We normally make voltage into 220V/50HZ/Single phase or 380V/50HZ/Three Phase. But it can be made according to clients' demand, like 110V/60HZ/Three phase and so on.

2.Q: How long is the guarantee?

A: We promise guarantee as half of one year for non-human damage factor.

3.Q: How should I do if meet some trouble while using?

A: Don't worry about that. We are always be pleased to provide using support to clients. We can take a video for showing how to resolve the problem, and write detail resolution to you.

Follow us